The hydraulic piston can be moved transversally through the use of a convenient handwheel, which allows you to position the cylinder on the exact point you want to work on, without having to move the material to be pressed.

The work platform is adjustable in height and its movement occurs by connecting the eyebolts to the cylinder with two chains.

The approach speed of this hydraulic workshop press is 25 mm/sec, while the working speed is 2 mm/sec.

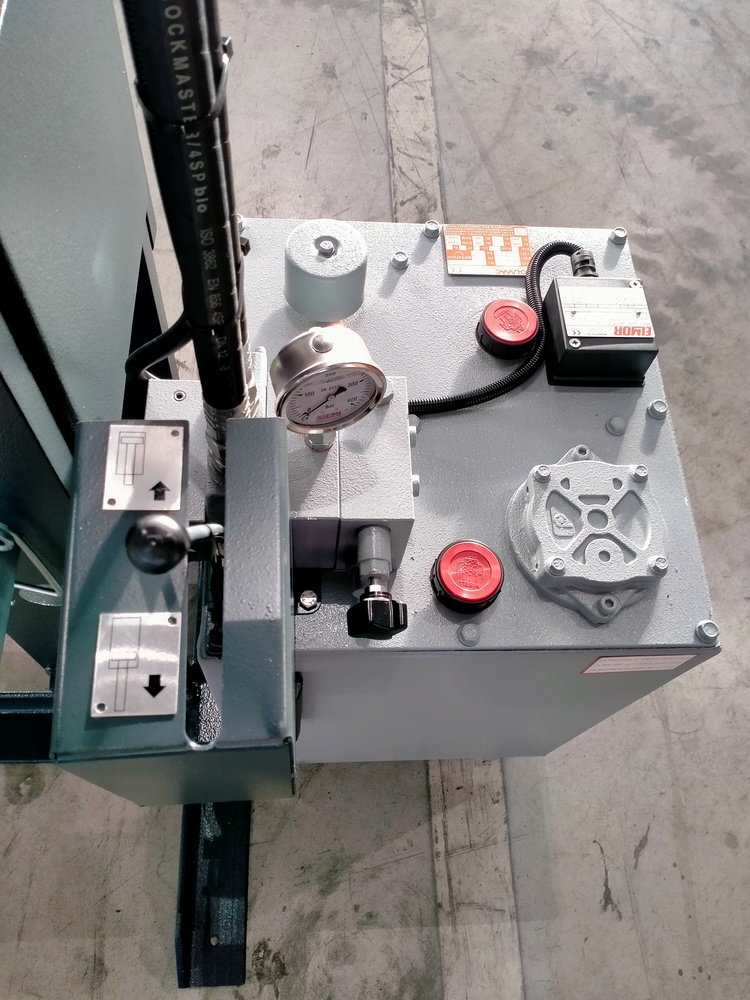

The press is operated by simultaneously using the lever and the button, as required by current safety regulations.

This hydraulic workshop press with movable piston is ideal for various processes, including straightening sheet metal, for assembling and dismantling bearings, bolts, washers, for carrying out molding or material deformation work.

The structure of the press is made of fully welded milled steel and this allows the machine to absorb even the highest pressures. The PSS hydraulic press is perfectly suited for intensive use in maintenance and repair workshops or even in industry.

The large front opening allows you to easily place long or wide pieces.

The work surface of the PSS hydraulic workshop press is hollow and this allows processing of the material at height. The work support surface is available as optional equipment.

For more information on the other planned workshop presses, click below: