The electro-hydraulic workshop press with movable table, model PBM 70, is suitable for carrying out various processes and repairs within a mechanical workshop. It can be used for straightening sheet metal and metals in general, as well as for carrying out various types of assembly.

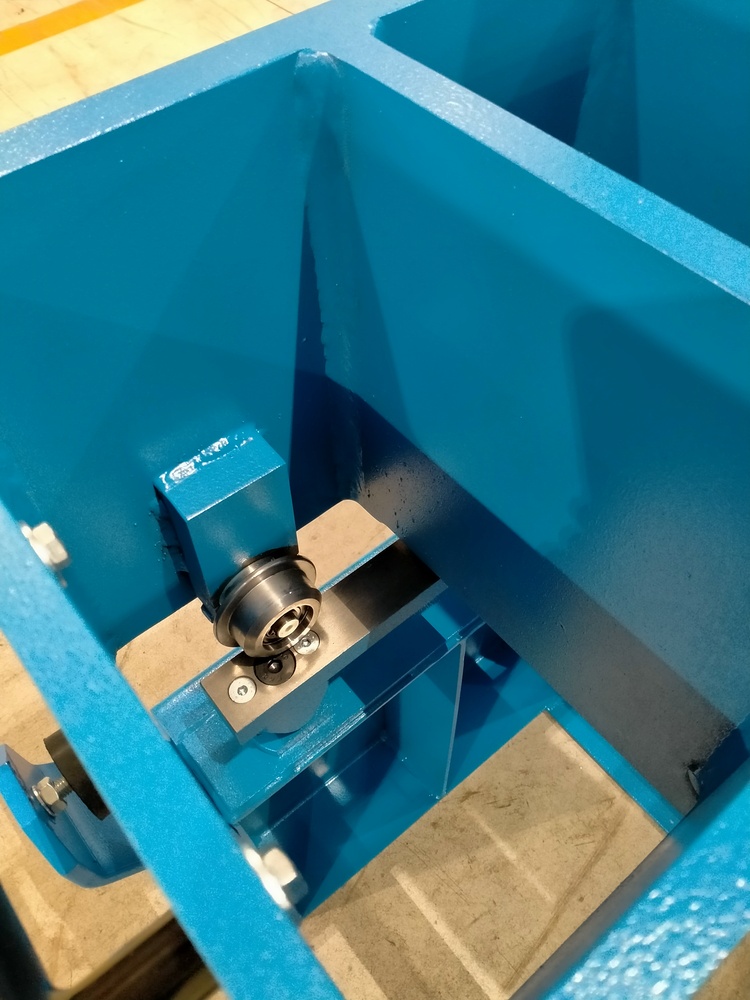

The support bench measures 870 x 600mm and slides along guides. This function is very useful for being able to load bulky and heavy materials, such as motors, using the crane and then being able to slide the table under the cylinder to carry out pressing work.

This electro-hydraulic workshop press with movable table develops a power of 70 tons.

The descent speed of the cylinder is 24 mm/sec, while the working speed is 5 mm/sec.

The hydraulic cylinder has a stroke of 500mm and a maximum distance between the piston and the table of 1100mm, as requested by the customer.

The upward and downward movement of the cylinder occurs through the simultaneous use of the lever and button.

The press was painted blue upon specific customer request.

Upon request, the machine can be equipped with the following accessories:

– End-of-stroke sensors to regulate the ascent and descent of the cylinder.

– Support plate to be placed on the sliding bench.

– Stem anti-rotation device.

– Sliding bench with hydraulic movement.

Click below for more information on our hydraulic workshop presses:

Electro-hydraulic press with sliding platform – PBM