This machine is equipped with a timer, which allows you to adjust how long the hydraulic cylinder must remain at the end of its stroke and a pressure switch that allows you to adjust the maximum pressure level.

Furthermore, this hydraulic press is equipped with a lock valve to maintain constant pressure. This valve works like a faucet and is installed near the master cylinder. Its function is to prevent oil leaks from returning inside the hydraulic circuit and by doing so, it allows the liquid level in the cylinder to be kept constant for the entire preset pressing time.

This electro-hydraulic metal forming press works in both manual and automatic modes.

Manual mode is normally used for adjusting the molds and the cylinder limit switch. In this function, the cylinder rises by holding down the appropriate button on the control panel.

In automatic mode, however, the cylinder rises automatically every time the operator stops pressing the double buttons during the descent phase or every time the pressing cycle is completed.

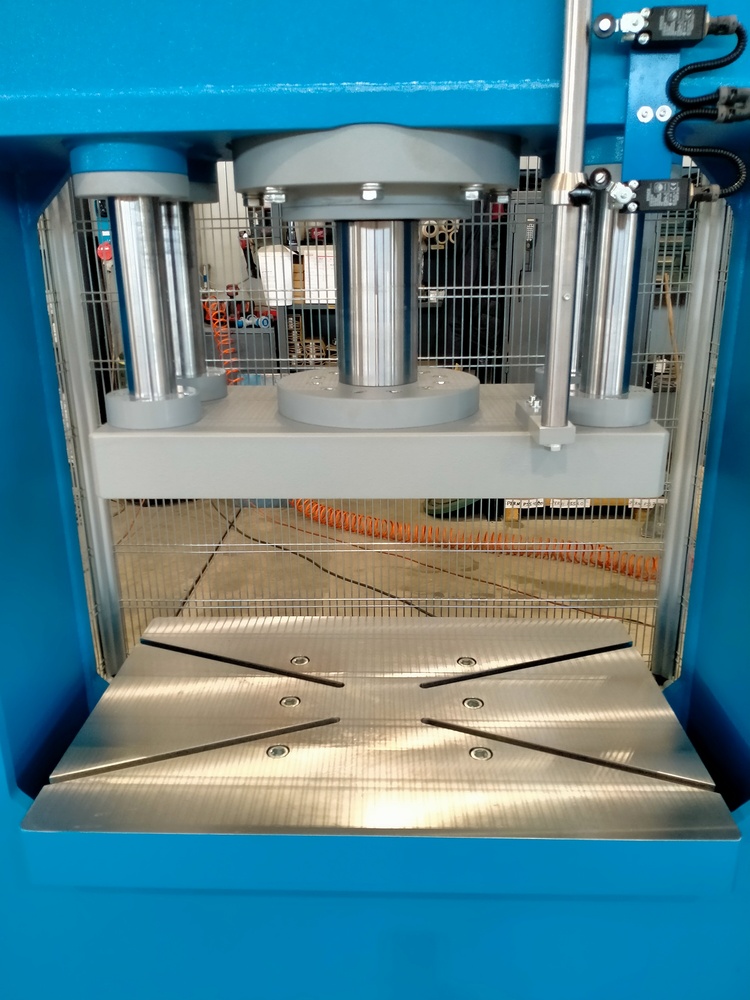

The cylinder has an approach speed of 25 mm/sec and its stroke is regulated via microswitches.

This double column hydraulic press develops a power of 100 tons and is protected by a metal mesh at the rear.

Click below for more information on this press model: