A new hydraulic press bending machine has just been produced and is ready to reach its final destination at a school in the Caribbean.

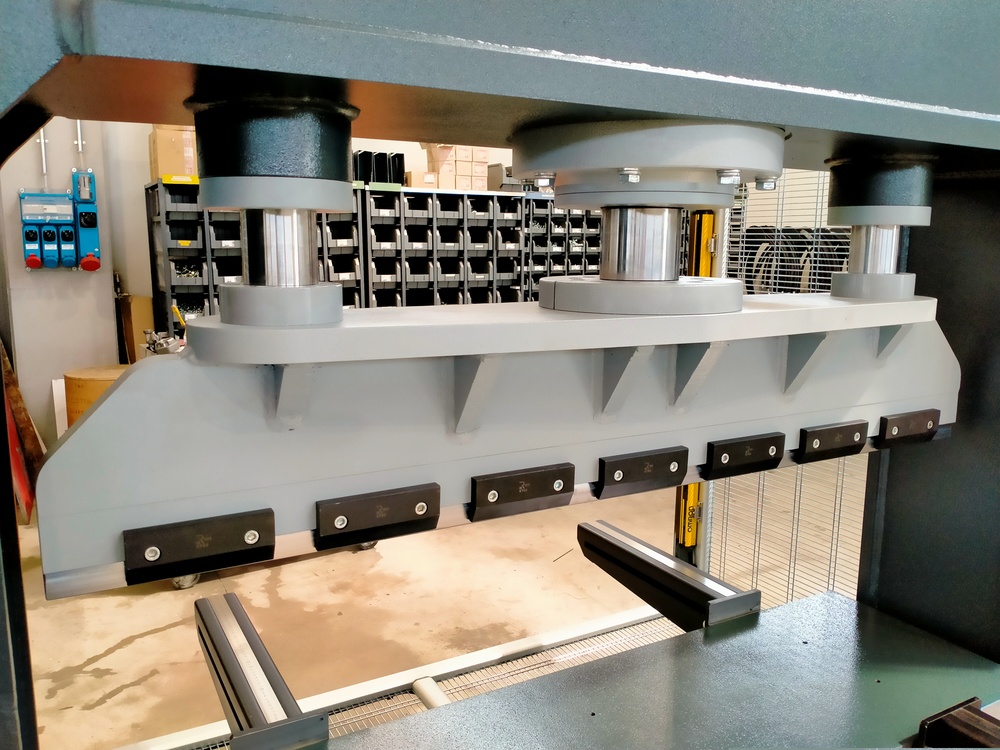

This press develops a power of 100 tons and has a distance between the columns of 1550mm, which allows it to bend very wide steel plates.

The machine is equipped with a pair of front supports equipped with millimeter scale. An adjustable stop is installed on the supports which allows micrometric locking in order to obtain greater precision of the fold you want to make.

This hydraulic press bending machine is also equipped with a large protective net on which immaterial barriers with photocells have been installed, which immediately block the descent of the cylinder in the event that an operator stands between them.

The press is regulated by a double pedal control and has a cylinder descent speed of under 10 mm/sec. This allows, according to safety regulations, to have your hands free during the pressing cycle and therefore to be able to move the piece to be bent.

All the bending working parameters are set via the Siemens KTP 700 Basic digital screen which allows you to store up to 100 different programs.

Click below for more information on the standard model:

Hydraulic press for bending steel – PDL