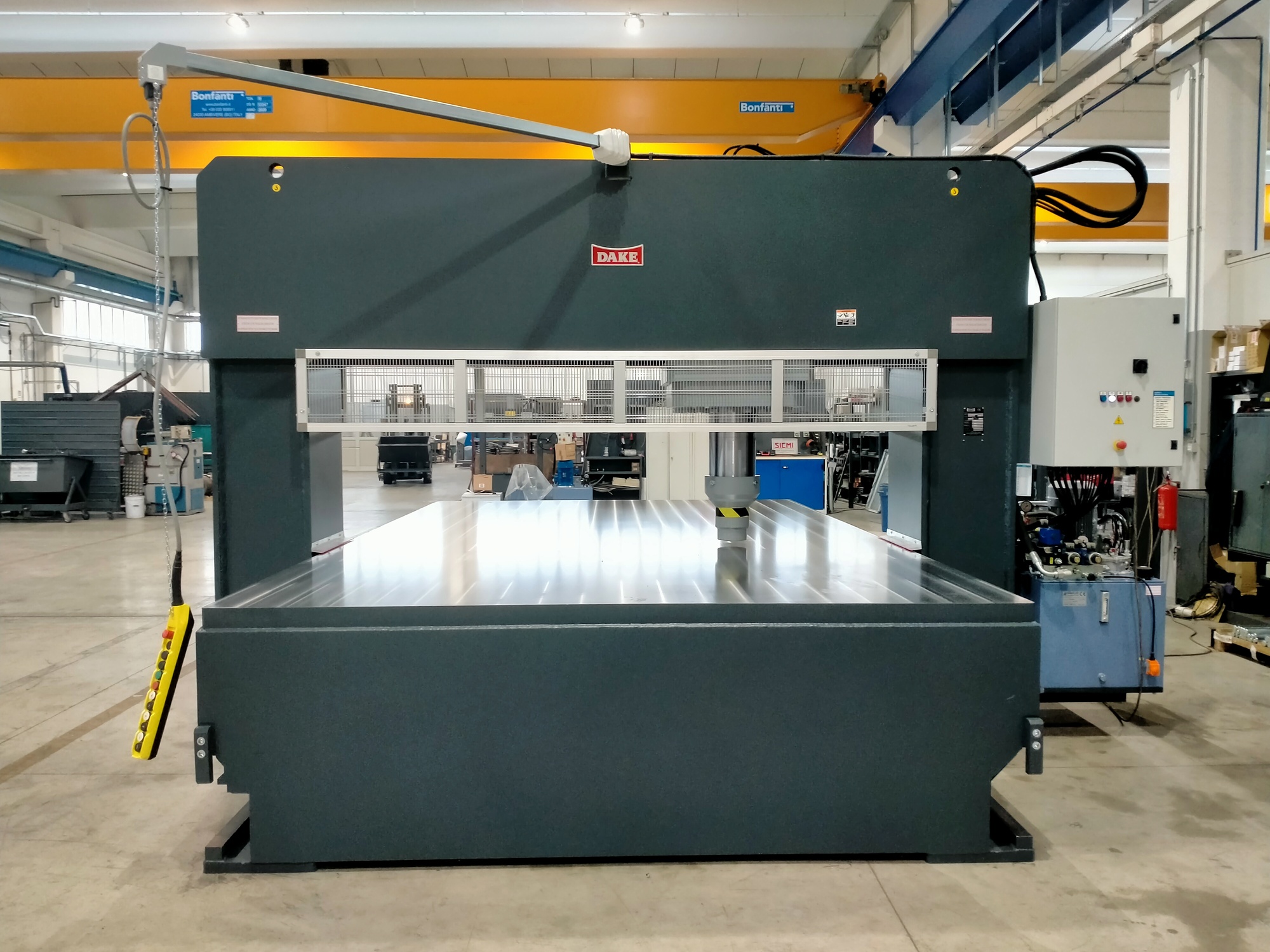

Our workshop has completed the production of a 400-ton gantry hydraulic straightening press.

This press is intended for the US market and will be used mainly for straightening sheet metal, metal profiles and for various carpentry jobs.

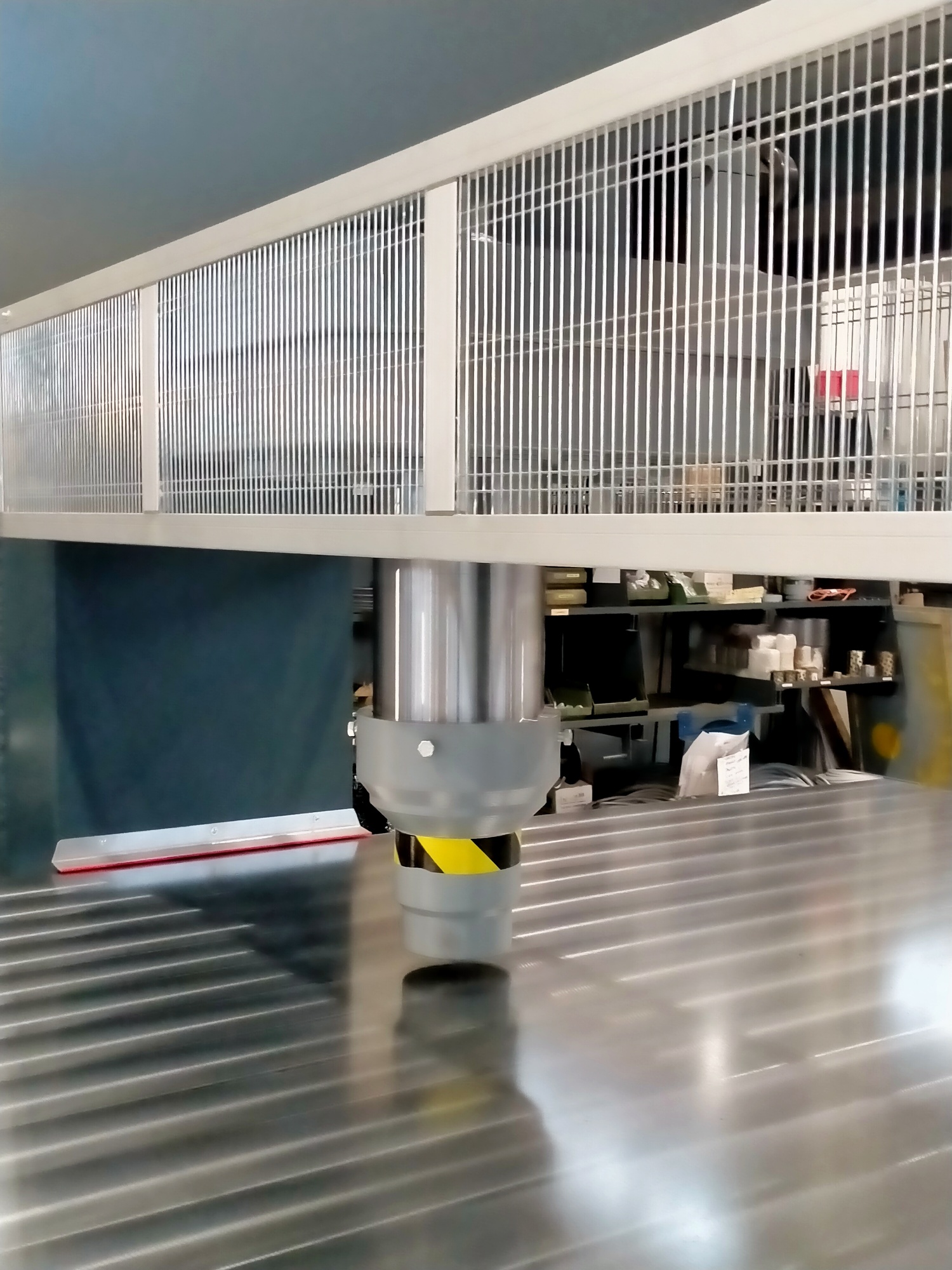

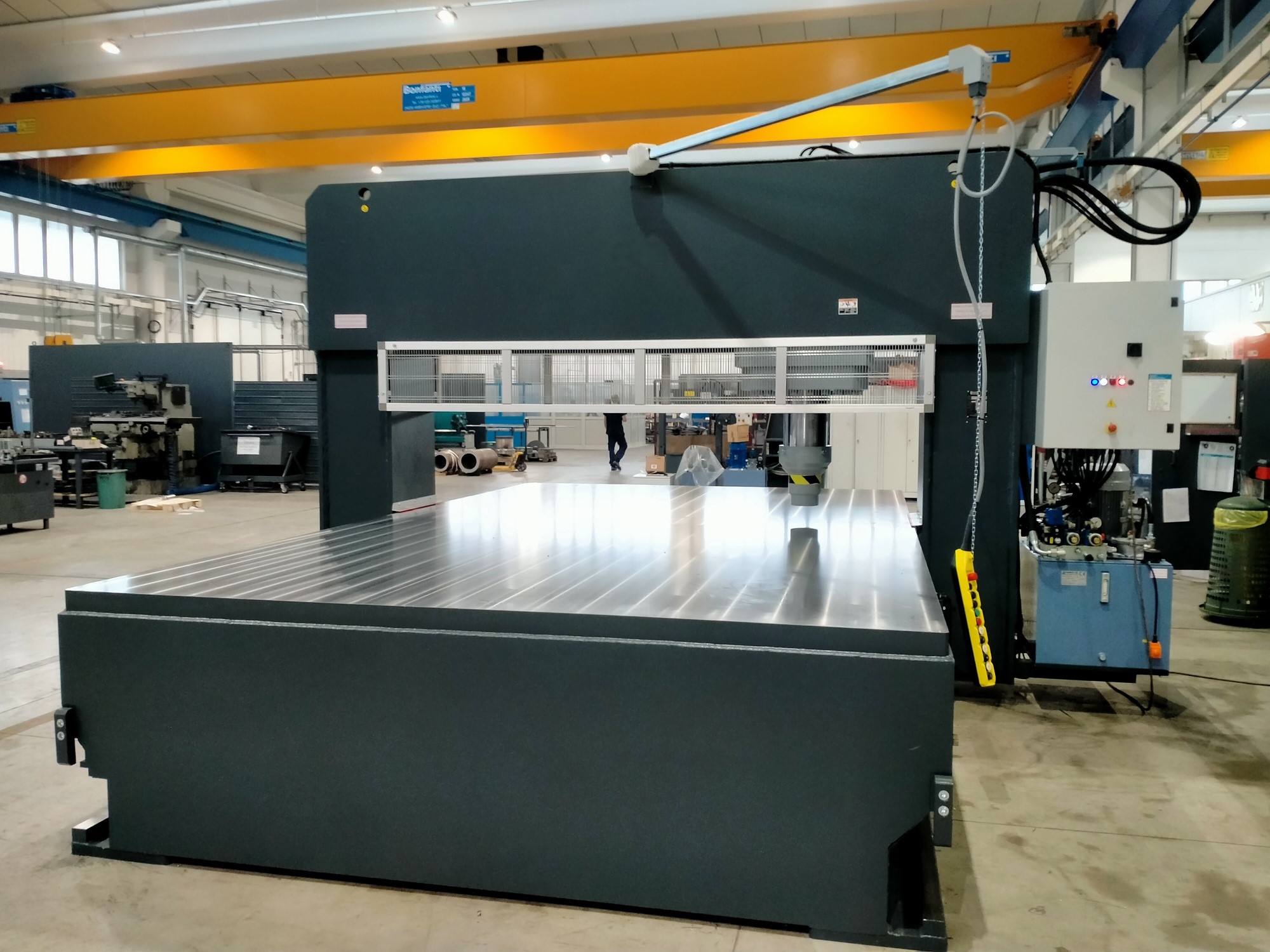

Thanks to the longitudinal movement of the upper frame, combined with the transverse movement of the cylinder, it is possible to reach any point of the material to be straightened without having to move it from the workbench.

The movement of the upper frame and the cylinder are managed through the use of a convenient pendant control panel that allows the operator to always be close to the piece to be straightened.

This 400-ton gantry hydraulic straightening press differs from other straightening presses thanks to the double speed of movement and approach of the hydraulic cylinder. In fact, a fast and a slower speed have been provided to allow the operator to carry out jobs where greater precision is required.

The stroke of the hydraulic cylinder is 500mm, while the distance between the stem and the work surface is 700mm.

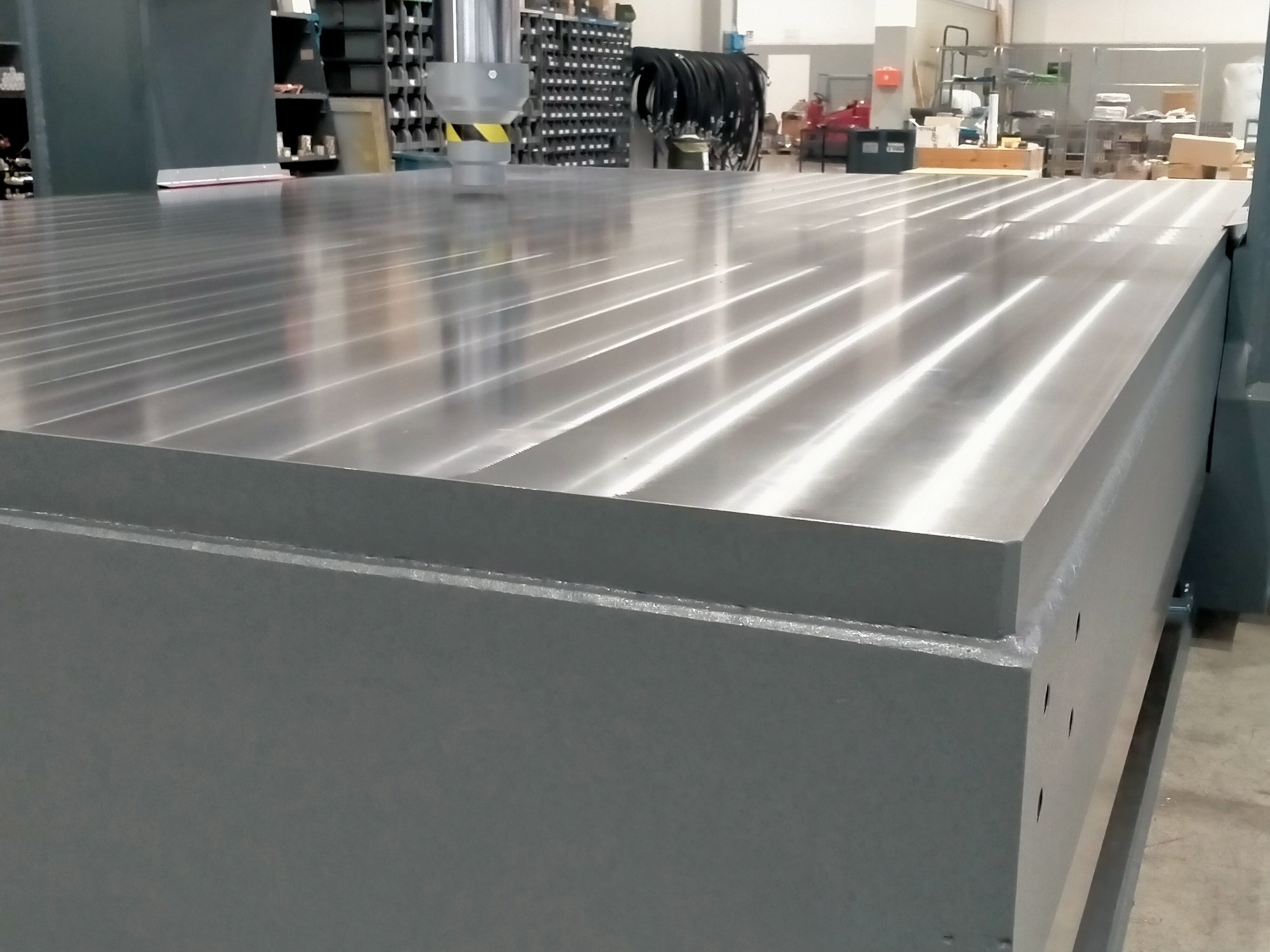

The support platform is completely milled on the surface and welded to the machine structure, so as to strengthen the press frame and optimize the leveling phases of the metal piece to be machined.

The press is equipped with a 7,5 kW hydraulic power unit with a 480V – 60Hz motor.

An air/oil heat exchanger is also supplied as standard equipment to improve cooling of the hydraulic circuit.