CUSTOMIZATION OF PRESSES

Special presses

industrial testing

custom hydraulic presses for industrial testing

This page presents some of the special hydraulic presses for industrial processes created in the past upon specific request of our customers.

hydraulic press for testing industrial valves

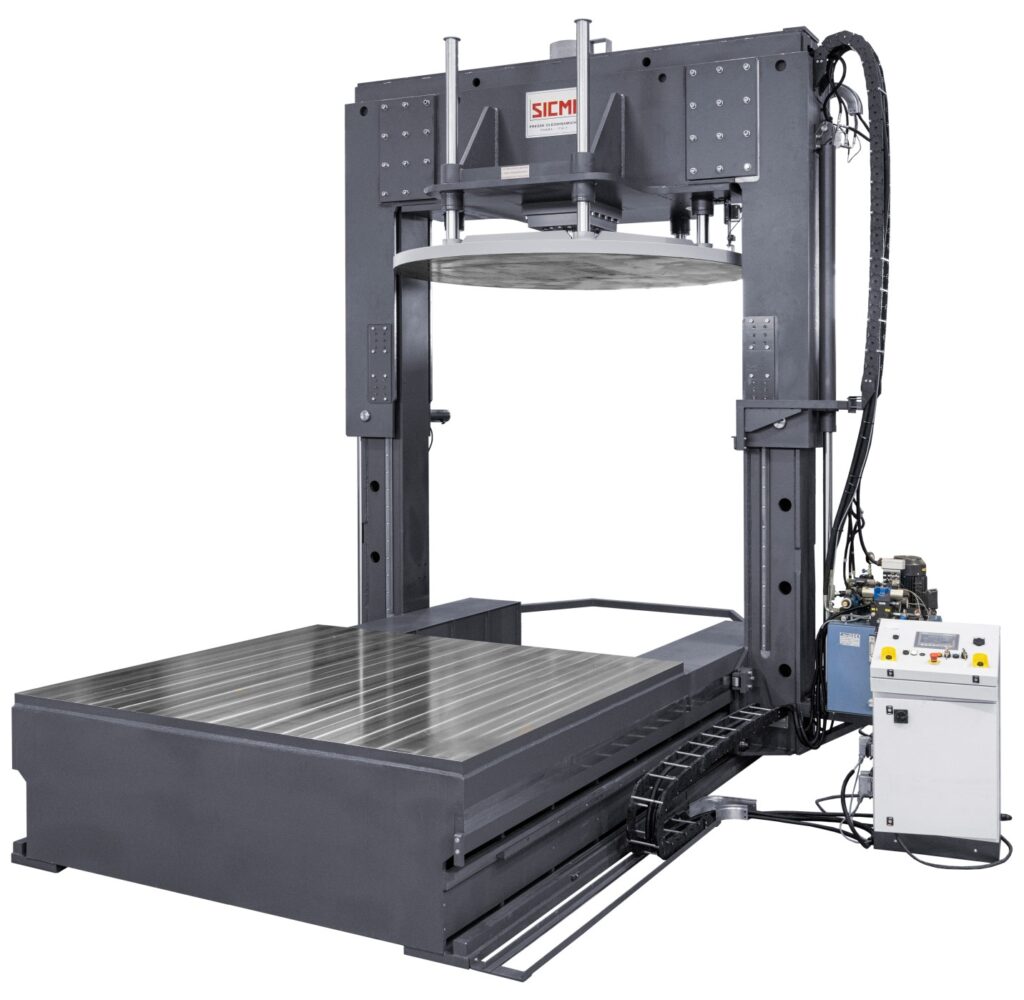

The PST 150 MM hydraulic press was specifically created to carry out industrial testing of large valves.

The completely milled lower work platform is fixed and is equipped with two rear extensions, while the upper frame is mobile with hydraulic movement and you have the possibility of positioning it completely outside the work area, thanks to the extensions present in the platform.

The upper upright is adjustable in height via the two lateral hydraulic cylinders with a stroke of 1600mm and the relative fixing of the upright occurs via special pins. These pins have a welded seat to facilitate insertion and safety detection sensors.

The upper work surface has a circular shape with a diameter of 2400mm and slides along guide columns which have the function of always keeping the surface perfectly aligned.

hydraulic press to compress large springs

The PTR 50 hydraulic press was designed for compressing large springs with a power of 50 tons.

The upper frame of the electro-hydraulic press has a large opening to be able to position the spring by lowering it from above and lowering it inside a special protection cage where the spring is blocked and made safe.

Due to the upper central opening in the frame of the workshop press, it was necessary to design a system of lateral cylinders that work in traction and allow the upper platform to descend and compress the central spring

The PTR 50 hydraulic press is operated by a small push-button panel and is equipped with a digital control and encoder to regulate the stroke of the cylinders.

hydraulic press for compressing industrial springs

The PSQ 90A hydraulic press was designed to compress large industrial springs.

The hydraulic press has a total clearance between the work surfaces of 3 meters and has an opening both on the upper upright and on the mobile platform to allow the spring to be compressed to be positioned from above using an overhead crane.

The mobile platform slides along four columns and is moved by a hydraulic cylinder with a stroke of 1000mm which develops a pressure thrust of 90 tons.

The structure of the PSQ 90A electro-hydraulic press is protected by metal nets to allow the operator to work in total safety.