OUR CUSTOMIZATIONS

Special presses

STAMPING

Custom hydraulic stamping presses

This page presents some of the hydraulic presses for molding made upon request of our customers.

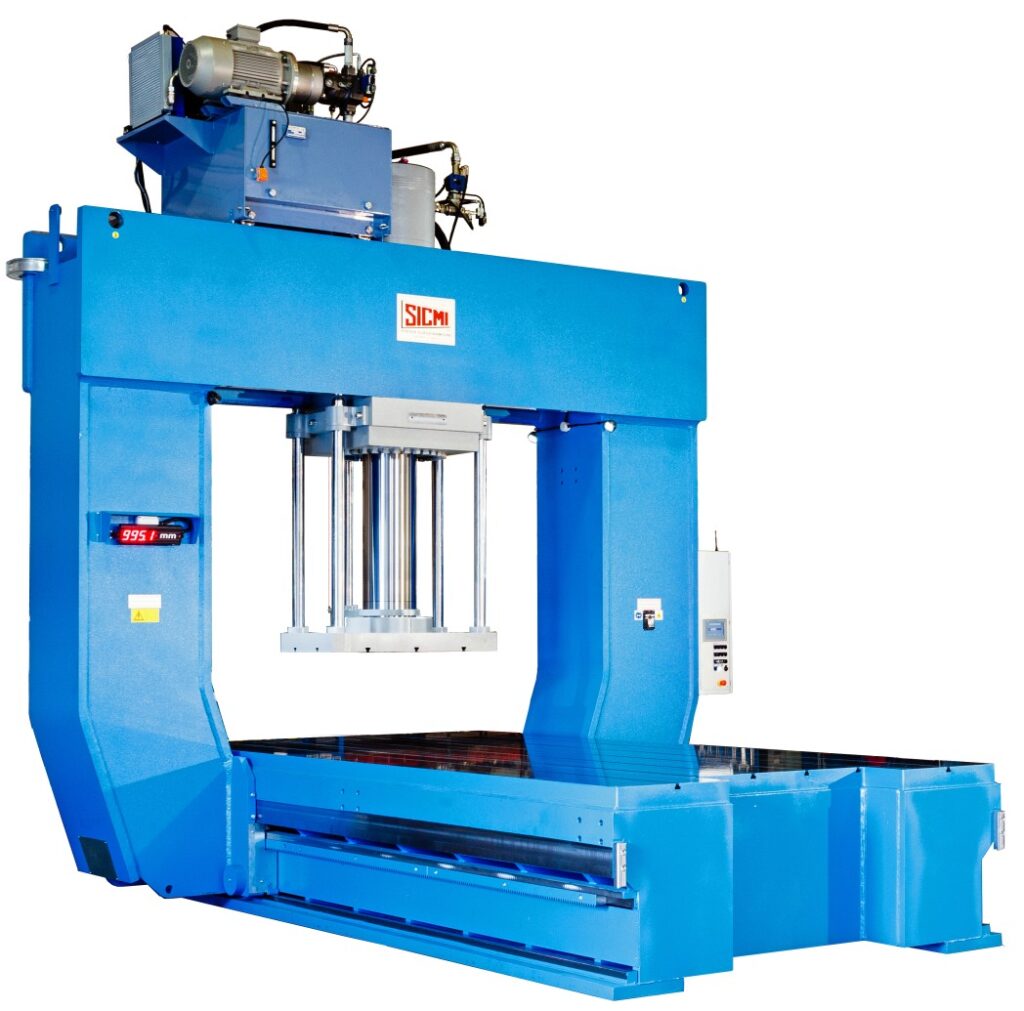

Hydraulic PRESS for large molds

The MST 260 hydraulic press was created to meet the needs of industrial molding with large-sized moulds.

This is made possible by the large 1800x1200mm work platform on which there are T-slots for fixing the moulds.

The upper mobile structure runs along prismatic guides with bronze runners which optimize the parallelism of the surfaces and avoid any type of oscillation of the structure. Furthermore, the prismatic guides also allow you to work off-center with respect to the main cylinder without this compromising the machining or damaging the press.

This version of the MST hydraulic press has a power of 260 tons and a cylinder stroke of 500mm.

The machine is equipped with photoelectric barriers and has been equipped with an openable front protection net equipped with safety sensors for the assembly and disassembly of the working molds.

Hydraulic PRESS for molding and hydroforming of pipes

Hydraulic press created on the specific request of a customer who needed to deform pipes using hydroforming, i.e. using high pressure water.

The PLC150+90 hydraulic press is equipped with a 150 ton main cylinder with a stroke of 500mm and a horizontal auxiliary cylinder with a power of 90 tons and a stroke of 1000mm.

The main cylinder has the function of closing the mold and blocking the metal piece to be worked, while the horizontal cylinder deforms the tube and increases the deforming effects exerted by the water pressure.

The activities of the PLC150+90 electro-hydraulic press are managed by the PLC and digital control, which allows you to customize the strokes of the cylinders and adjust the pressing times.

The machine has been equipped with sliding front guards with safety sensors.

Hydraulic stamping and straightening press

The PMM 600 mechanical workshop press has the extraordinary characteristic of being able to carry out both stamping and sheet metal straightening operations.

This is made possible thanks to the replacement of the upper mobile floor.

The machine is equipped with a mobile upright with hydraulic movement on which a mechanical stop is installed to carry out the molding operations in the exact position.

The upper molding surface slides along 4 guides for greater stability and working precision.

When the hydraulic press is used for straightening operations, it is sufficient to remove the upper molding surface and replace it with the punch for straightening the sheet metal.

This hydraulic press is equipped with a large working table of 2500x5000mm on which there are T-slots for fixing the moulds.

The stroke of the main cylinder is 1000mm, while the distance between the two planes is 2000mm.

4-Column Hydraulic molding press

The MQM 200 4-column hydraulic press with prismatic guides and light barriers. This state-of-the-art machine offers outstanding performance and uncompromising safety.

The four fixed uprights guarantee incomparable stability during the molding process, ensuring precise and consistent results. The prismatic guides allow a fluid and uniform movement, eliminating any friction and guaranteeing impeccable workmanship.

This electro-hydraulic press is equipped with light curtains, an advanced safety system that detects the presence of objects or people, immediately interrupting the operation to protect operators and prevent accidents.

The versatility of this press makes it ideal for various molding applications, both for small productions and for large-scale jobs with a cylinder approach speed of 125 mm/sec.