This 100 ton hydraulic press allows you to carry out deep drawing and stamping operations on sheet metal and metals in general.

The machine was created starting from our standard PST 100 model on which we carried out a whole series of modifications, including increasing the distance between the columns, increasing the size of the work table and its height from the ground.

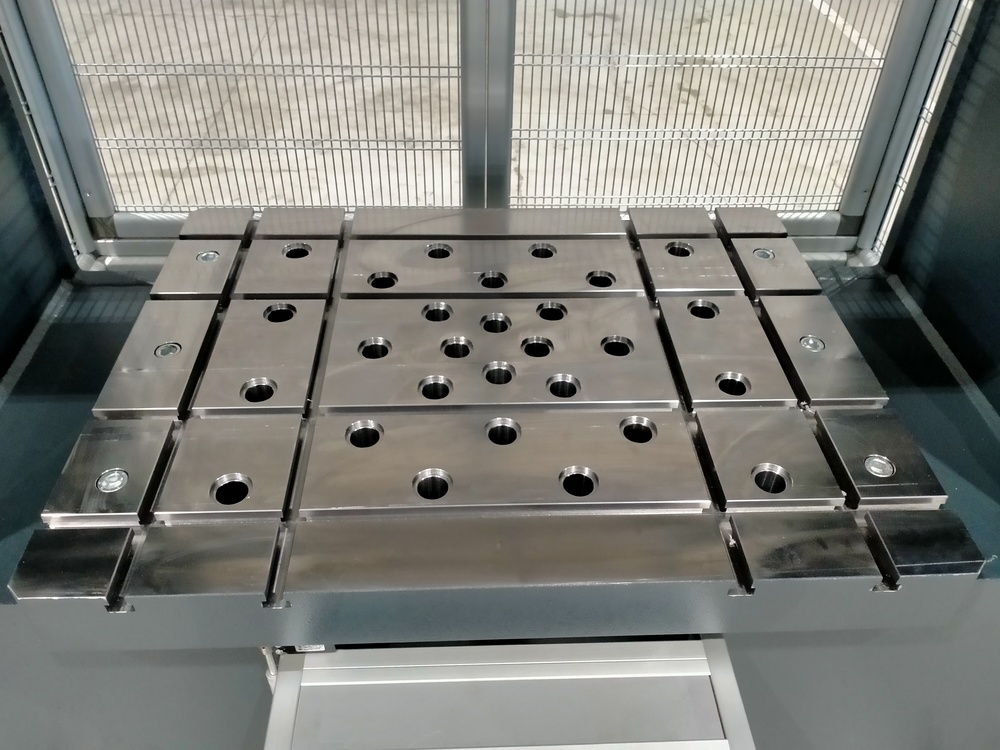

The worktop was produced using 40CMD8 material capable of withstanding a force of 1100 N/mm2.

Under the lower work table we have inserted a 40 ton hydraulic cushion which is equipped with sensors for adjusting the cylinder, whose maximum stroke is 250mm with a speed of 43 mm/sec.

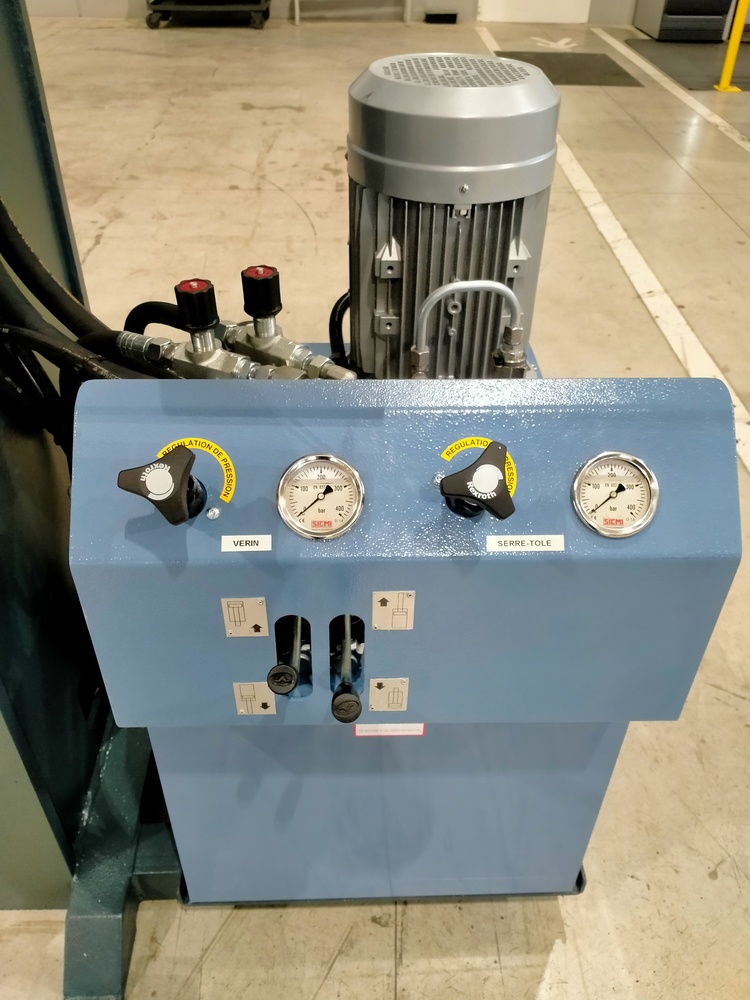

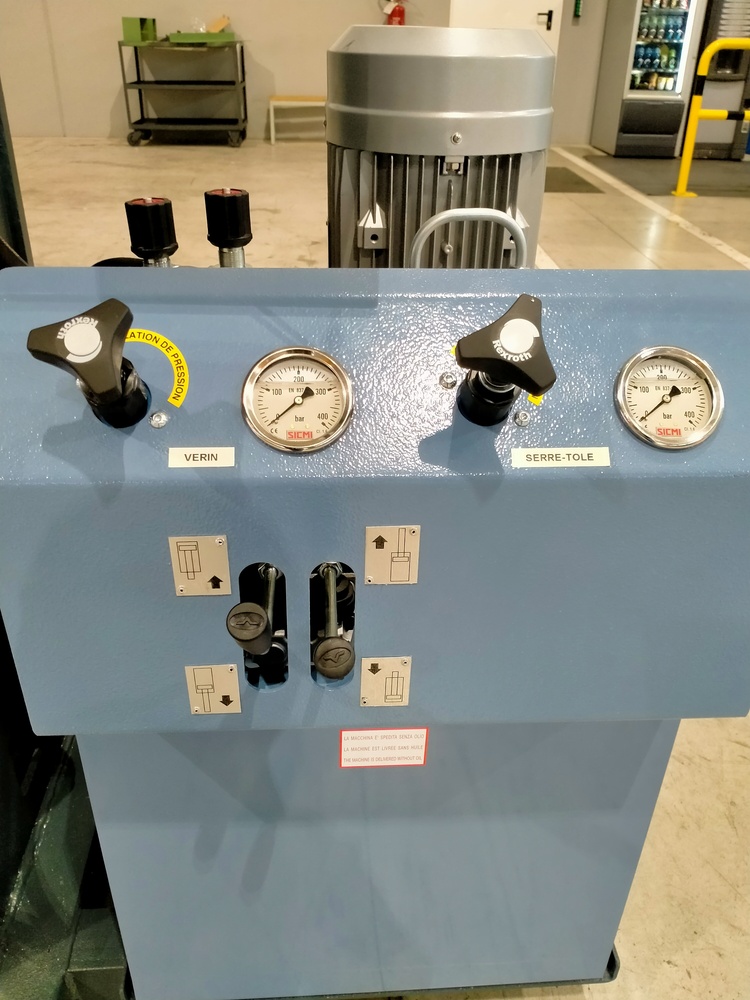

The hydraulic molding press with hydraulic cushion is operated by using 2 levers, to be used simultaneously with the button located on the electrical panel, as required by current European standards in terms of safety. One lever activates the descent and ascent of the main cylinder, while the other lever is used to move the hydraulic cushion.

The back of the hydraulic press is protected by a metal protective grill that can be opened, so as to have access to the work table.

Click below for more information on the standard model: