Our workshop has just completed the production of two hydraulic shaping presses, which develop a power of 150 tons.

These machines are equipped with a lock valve which allows the oil level inside the cylinder to be kept constant throughout the pressing cycle.

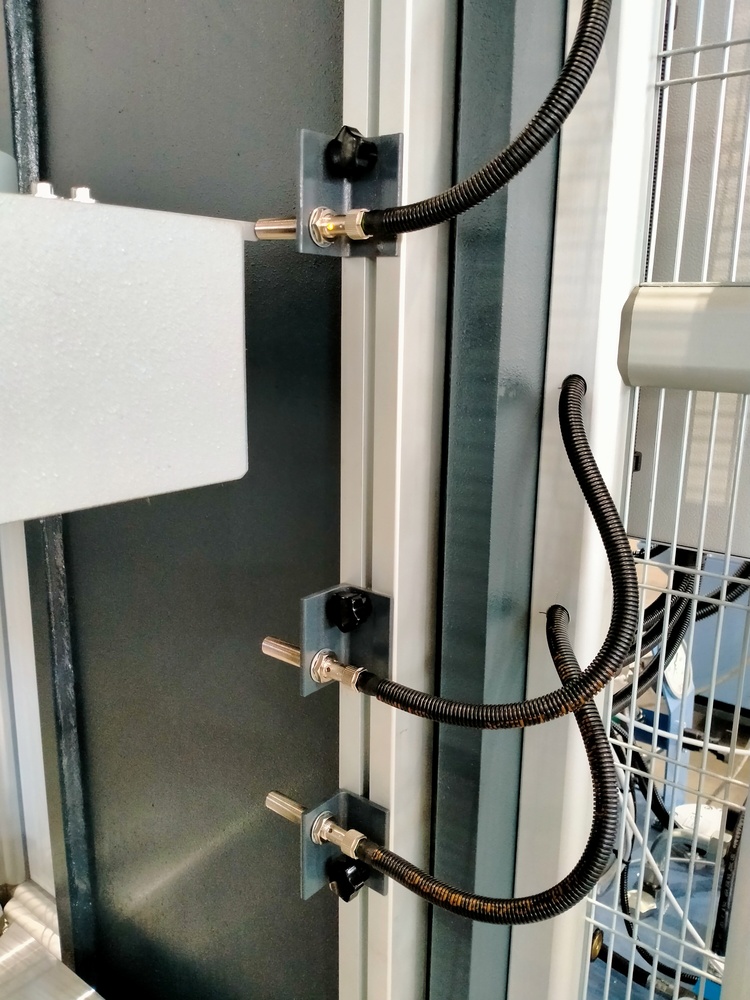

Given that the material that the customer wants to process has a tendency to compress during processing and reduce in thickness, two pressure switches have been installed which monitor the minimum and maximum processing pressure. This means that when the pressure drops to a certain level, the pressure switch that monitors the minimum pressure sends an impulse to the hydraulic control unit, which introduces a certain quantity of oil into the circuit until the preset maximum pressure is reached.

Since the presses will be used in long production cycles, the hydraulic power unit is equipped with a heat exchanger which prevents the hydraulic circuit from overheating.

The presses are equipped with a system for separate speed management, which allows you to adjust the point at which to switch from the approach speed to the working speed.

These hydraulic shaping presses are equipped with fixed rear protection nets and opening front nets, equipped with safety sensors.

Click here for more information on: hydraulic presses for shaping.