The hydraulic shop press with motorized platform, PFF 150 MD model, is the ideal machine for carrying out straightening and sheet metal bending operations or for carrying out various activities within a mechanical workshop.

The hydraulic lifting of the table and the motorized transverse movement of the cylinder make this hydraulic press unique on the market.

The double column structure of the press is made of fully welded milled steel and this allows the press to be extremely resistant and solid. The hydraulic shop press with motorized platform, PFF, is suitable for both intensive use in mechanical workshops and for use in industrial plants.

The wide front opening between the two uprights allows for easy positioning of long or wide pieces.

The work surface of this electro-hydraulic motorized workshop press is hollow, which facilitates the processing of the material at height. Work support plates are available as optional equipment.

The main feature of the PFF hydraulic press that distinguishes it from other models is the hydraulic lifting of the work platform. The latter is blocked with the use of steel pipes so as to eliminate any unwanted movements.

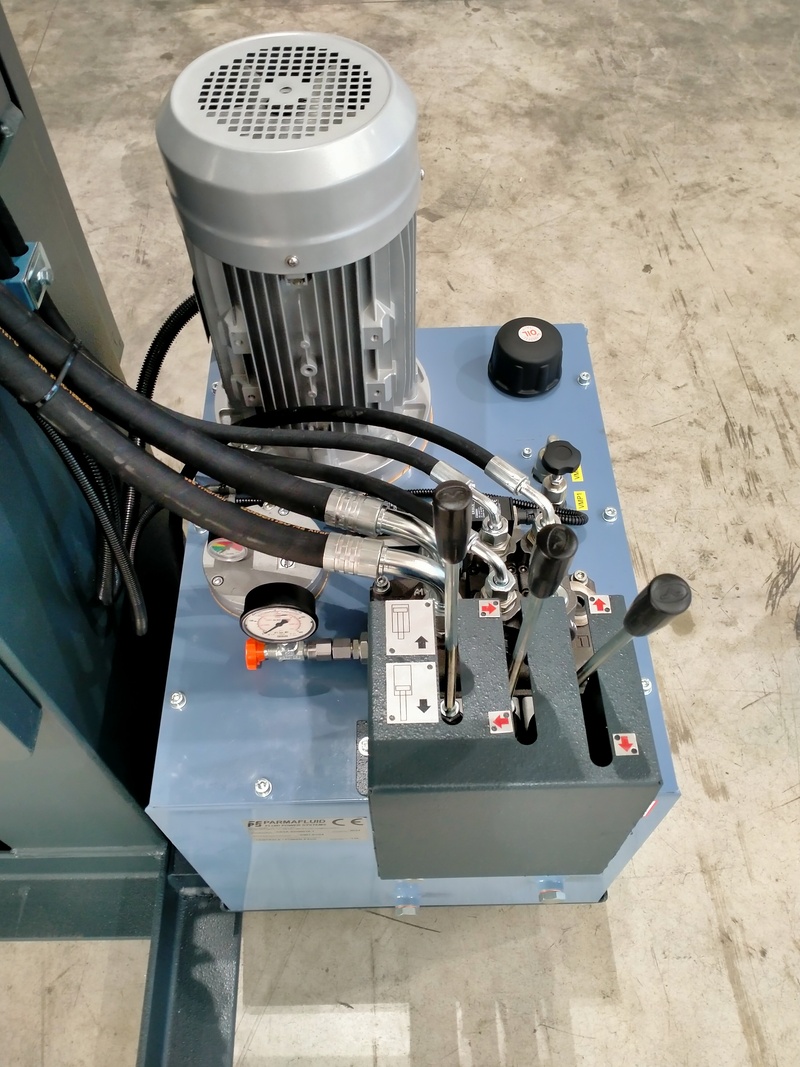

As far as the hydraulic cylinder is concerned, the customer can choose between a PFF hydraulic press model with a fixed cylinder, or he can opt for the version with a mobile cylinder with transversal displacement. This function is manually controlled via a handwheel in models up to 100 tons and with hydraulic movement from 150 tons upwards.

The hydraulic operating controls require the simultaneous use of the lever and the button.