Electric and hydraulic gantry press for sheet metal straightening – PMM-HY

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Electric and hydraulic gantry press specifically designed for high precision sheet metal straightening and deformation operations with significant energy savings.

– Electrical movements to reach the sheet metal with millimetric precision without moving it from the work bench.

– Hydraulic master cylinder with power accumulator to minimize the use of hydraulic oil.

– Reading of the sheet metal via laser capable of identifying the points where the sheet metal is deformed. In the automatic cycle the press positions itself at the point where it needs to work.

– Wireless remote control designed for safe use and accurate to the millimetre.

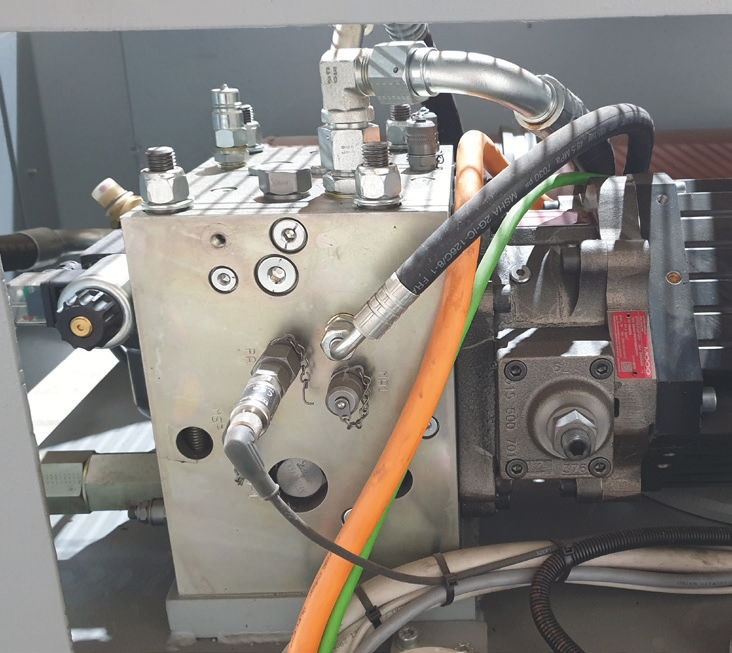

Electro-hydrostatic unit

The innovation of the PMM-HY model: master cylinder drive system using an Electro-Hydrostatic Motor-Pump Unit (EPU). This innovative system provides the following benefits:

- High precision of movements, with high dynamism and flexibility in configurations to provide maximum adaptability to the type of work to be performed.

- High energy efficiency as it is activated only when activated by the operator.

- Eliminates the need for complex hydraulic power packs and piping, reducing footprint.

- Compact design with particular interface that allows direct connection to the cylinders reducing additional spaces.

- Reduced environmental and acoustic impact.

Press structure

- Highly rigid electro-welded steel structure consisting of upright and platform.

- The upright is a single electro-welded body that slides on the guides of the platform and the main cylinder is positioned on the upper frame, which slides to the right and left by means of steel wheels.

- The structure is calculated to have maximum rigidity and minimum bending at maximum effort to ensure perfect functionality for the operations to be performed.

Hydraulic plant

- The hydraulic unit is positioned on the upper part of the mast with the use of two-stage pumps and the electric motor, representing the best compromise between size, performance and noise.

- The accumulator allows to reduce the quantity of oil present in the press.

- The cylinder’s descent speeds are 3 and can be programmed and operated according to need.

- Brushless motor and servovalve group allow reduced consumption and only use of the oil inside the cylinder.

Electrical system

- The electric and hydraulic gantry press is equipped with a control lectern with Touch-screen and buttons that allow you to set the working parameters and constantly view the positions.

- Complete control of the functions and cycles of the press in safety.

- The data of the readings made by the laser are displayed on the screen so as to allow the operator to act either manually or automatically where necessary.

- The press is equipped with a remote control to carry out the operations in total freedom.

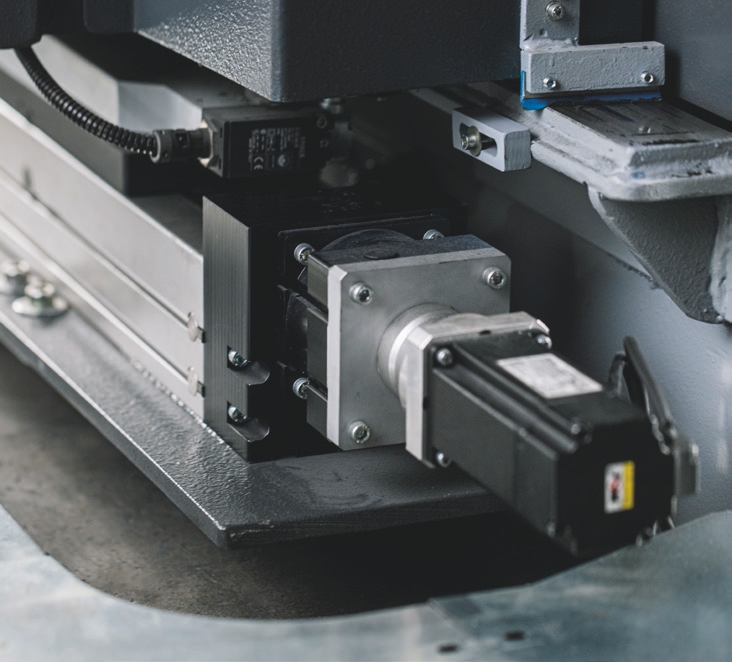

Hydraulic Cylinder and Electric Auxiliary Cylinders

- Specially designed for the specific needs of use of the press.

- In the hydraulic cylinder, in addition to the particular care of the internal surfaces and the rod, high quality gaskets are used to optimize the seal and friction.

- The electric cylinders allow for accurate movement precision.