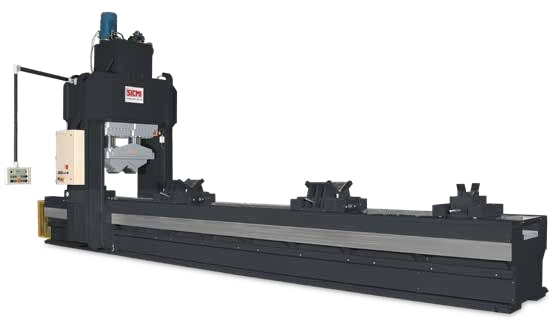

Hydraulic tube straightening press with travelling gantry – PRT

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Hydraulic tube straightening press with travelling gantry designed for flattening pipes, bars and round metal profiles.

The PRT electro-hydraulic press consists of an upper frame which slides along the main base of the press via a hydraulic motor.

On the lower base there are 4 manually operated sliding supports on which the metal pipe to be straightened is placed.

The two central supports have the main purpose of supporting the metal profile during the pressing phases, while the two lateral supports, one of which is motorized, have the function of lifting and rotating the tube.

The hydraulic double speed cylinder is positioned on the mobile upright and the necessary equipment is installed on it to carry out the straightening operations of the metal pipe.

This hydraulic tube straightening press with travelling gantry is supplied as standard with Rexroth solenoid valves, with Siemens PLC and with Siemens KTP700 touchscreen display for setting the work quotas and for setting the pressing times and operating pressure.

The control panel is installed on one side of the mobile frame and manages the hydraulic movements of the press.

It is equipped with a mobile arm that allows the operator to adjust the working position and to be close to the piece to be straightened.

The control panel works with the system of double buttons to be pressed simultaneously, so as to force the operator to have both hands busy, as required by current European safety standards.

Accessories

- Installation of proportional solenoid valves to improve the accuracy of cylinder position and pressure

- Air/oil heat exchanger with decompression valve