Hydraulic shop press (cylinder stroke 350mm) – PSS-NC

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

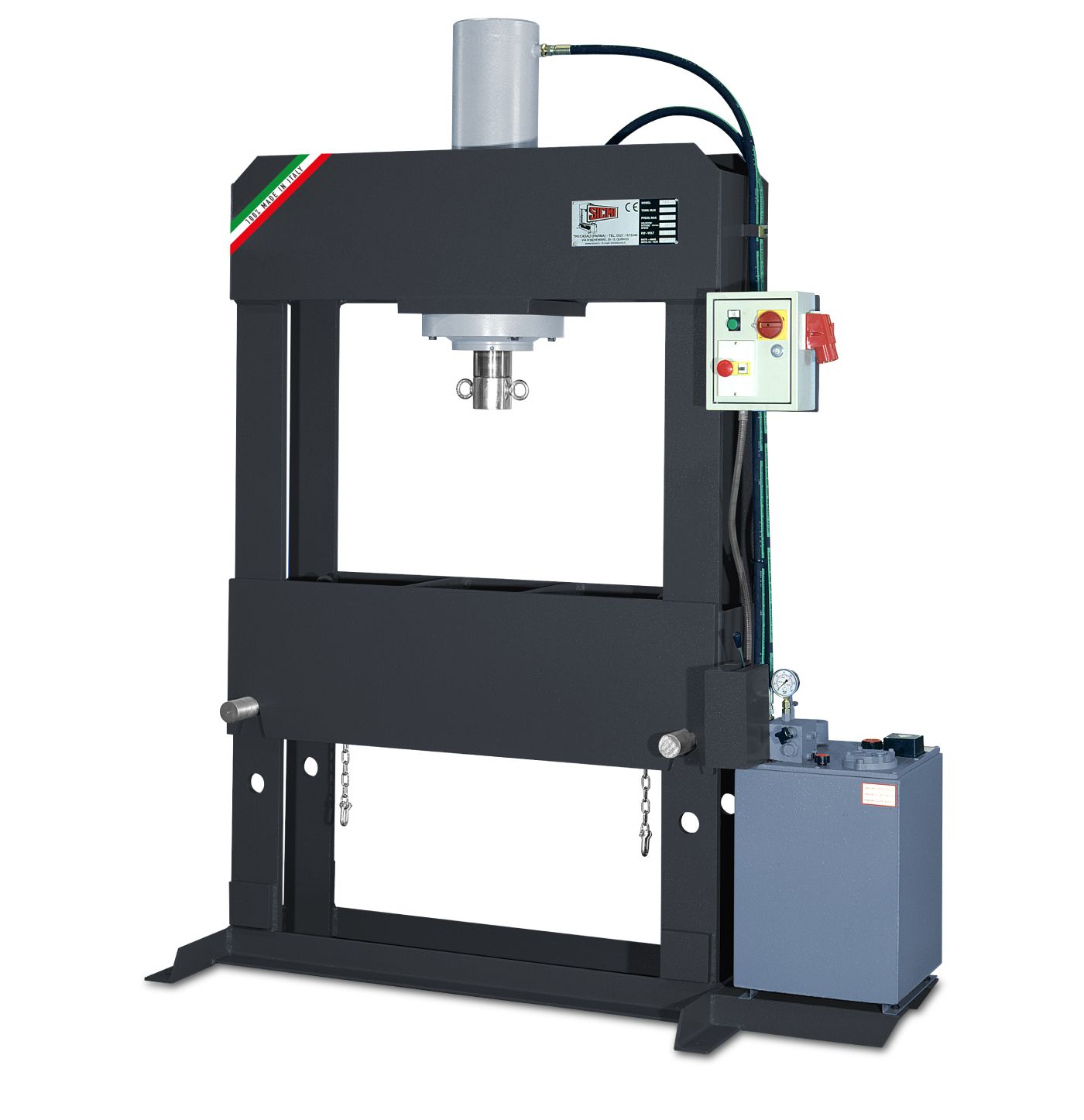

Hydraulic shop press suitable for various processes, including straightening sheet metal, assembling and dismantling bearings, bolts, washers and for carrying out molding or material deformation work.

The press frame is made of fully welded milled steel and this allows the machine to absorb even the highest pressures. The PSS-NC hydraulic press is therefore suitable for intensive use in maintenance and repair workshops or even in industrial plants.

The large front opening allows you to easily place long or wide pieces.

The work surface of the PSS-NC hydraulic workshop press is hollow and this allows the material to be processed at height. The work support surface is available as optional equipment.

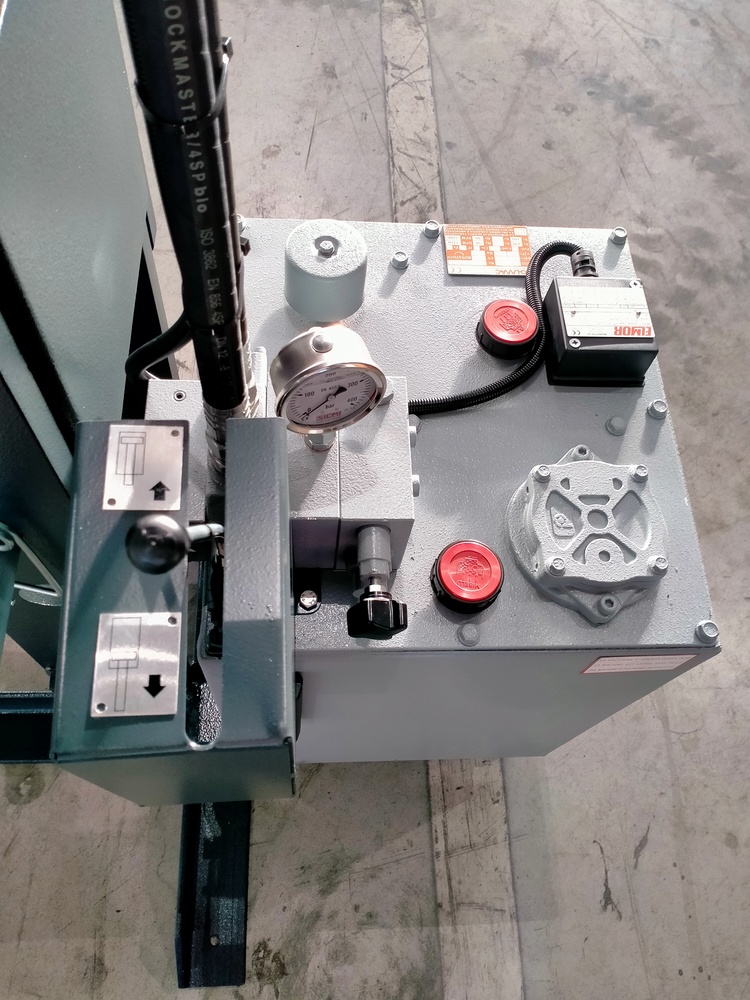

The PSS-NC press is equipped with a two-speed control unit which is activated by means of the simultaneous use of the lever and the button, as required by current CE safety regulations and the cylinder has a stroke of 350mm and a maximum speed of 29 mm/sec.

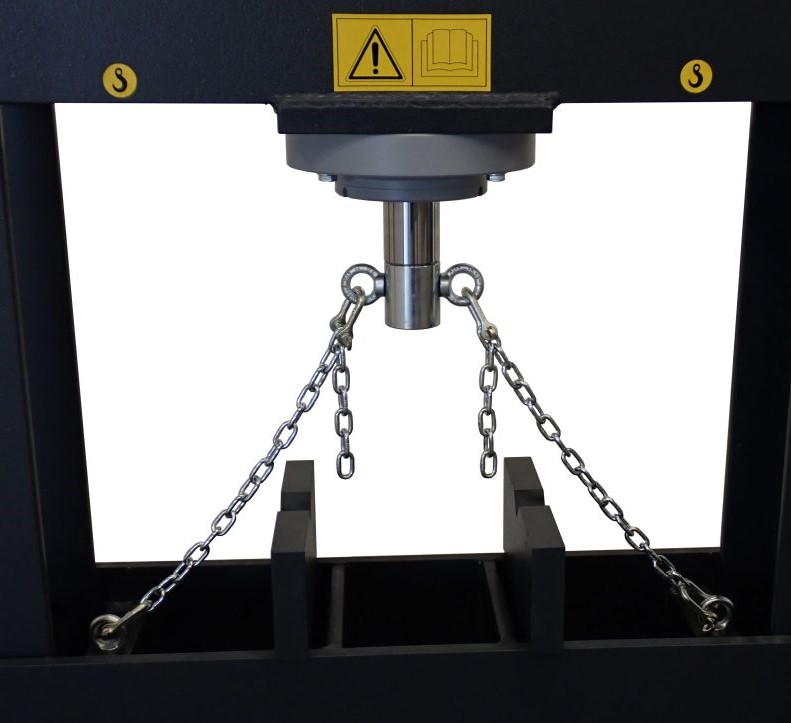

The lifting of the work platform occurs via a chain to be connected to the hydraulic cylinder and the blocking of the work surface is carried out using steel tubes, which eliminate any unwanted movements.

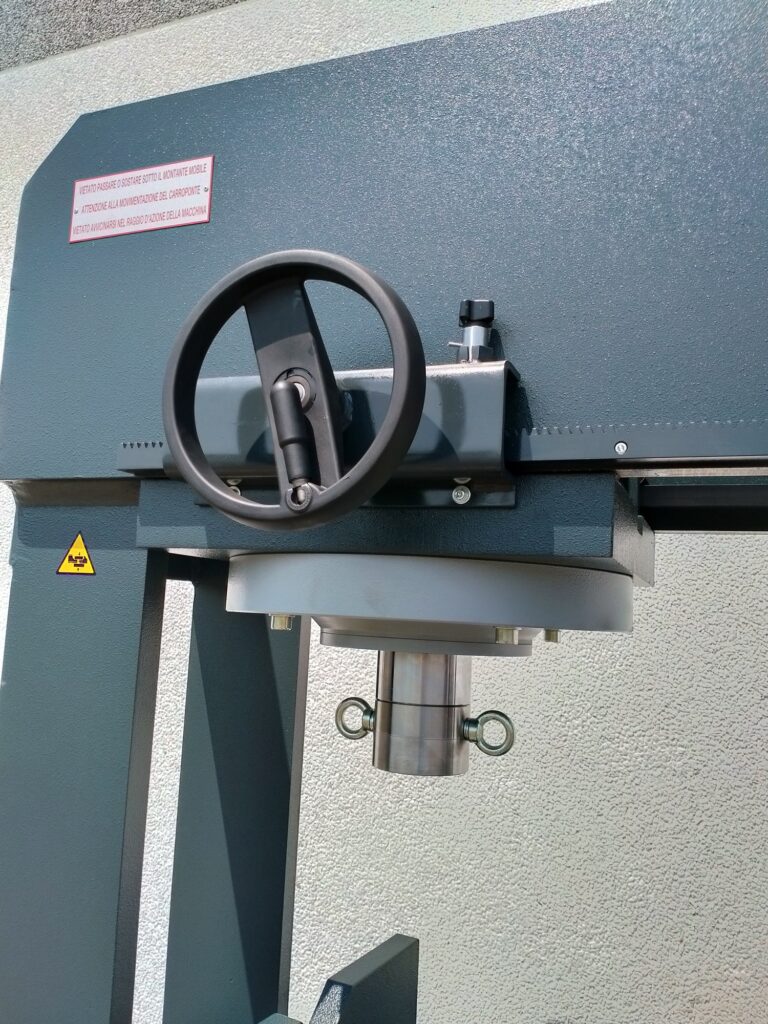

The PSS-NC hydraulic shop press is also supplied with a transverse movement mobile cylinder with manual control. This function is very useful because it allows you to move the cylinder laterally and then lower it to the exact point of the sheet metal you want to work on, without having to move the metal piece.

The PSS-NC electro-hydraulic press is available as standard from 20 to 150 tons.