Multipurpose hydraulic press for bending, molding and straightening – PSL

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Multipurpose universal hydraulic press for bending, stamping and straightening.

It allows you to carry out up to 3 different processes in the complete version within a mechanical workshop.

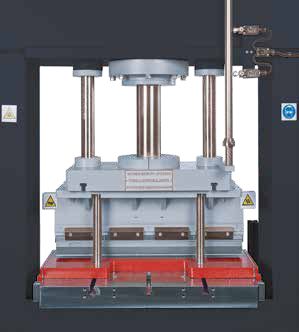

BASIC MODEL

The basic model of the PSL hydraulic press allows you to carry out stamping operations, as well as sheet metal straightening. In this version the press is composed of an upper and lower plate with T-shaped grooves and a punch for straightening metals.

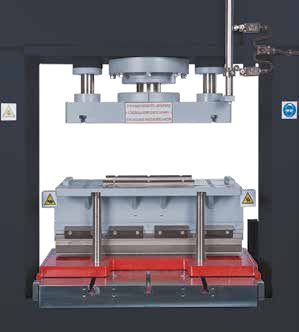

COMPLETE MODEL

The complete model of the hydraulic press includes the addition of a support and punch for performing bending work, a V-shaped prism and front sheet metal supports. With the complete model it is therefore possible to carry out 3 different processes: stamping, straightening and bending of the sheet metal.

The PSL electro-hydraulic press is supplied in 70 ton, 100 ton and 150 ton models and is available with both semi-automatic and automatic operation.

Semi-automatic operation

This system provides for the simultaneous use of the lever and the ignition button and is equipped with end-of-stroke sensors for the rod which regulate the ascent and descent of the cylinder.

Automatic operation

In the automatic version, the multipurpose hydraulic press for bending, molding and straightening, model PSL, can be operated through the simultaneous use of the double buttons for approach speeds up to 29 mm/sec or with the pedal for cylinder approach speeds within 10 mm/sec. Both the pushbutton and the pedals are supplied as standard in this version.

Also in this case it is supplied with cylinder end-of-stroke sensors and provides for the automatic ascent of the work surface.

The automatic model also includes the installation of the Siemens PLC and the Rexroth solenoid valves.