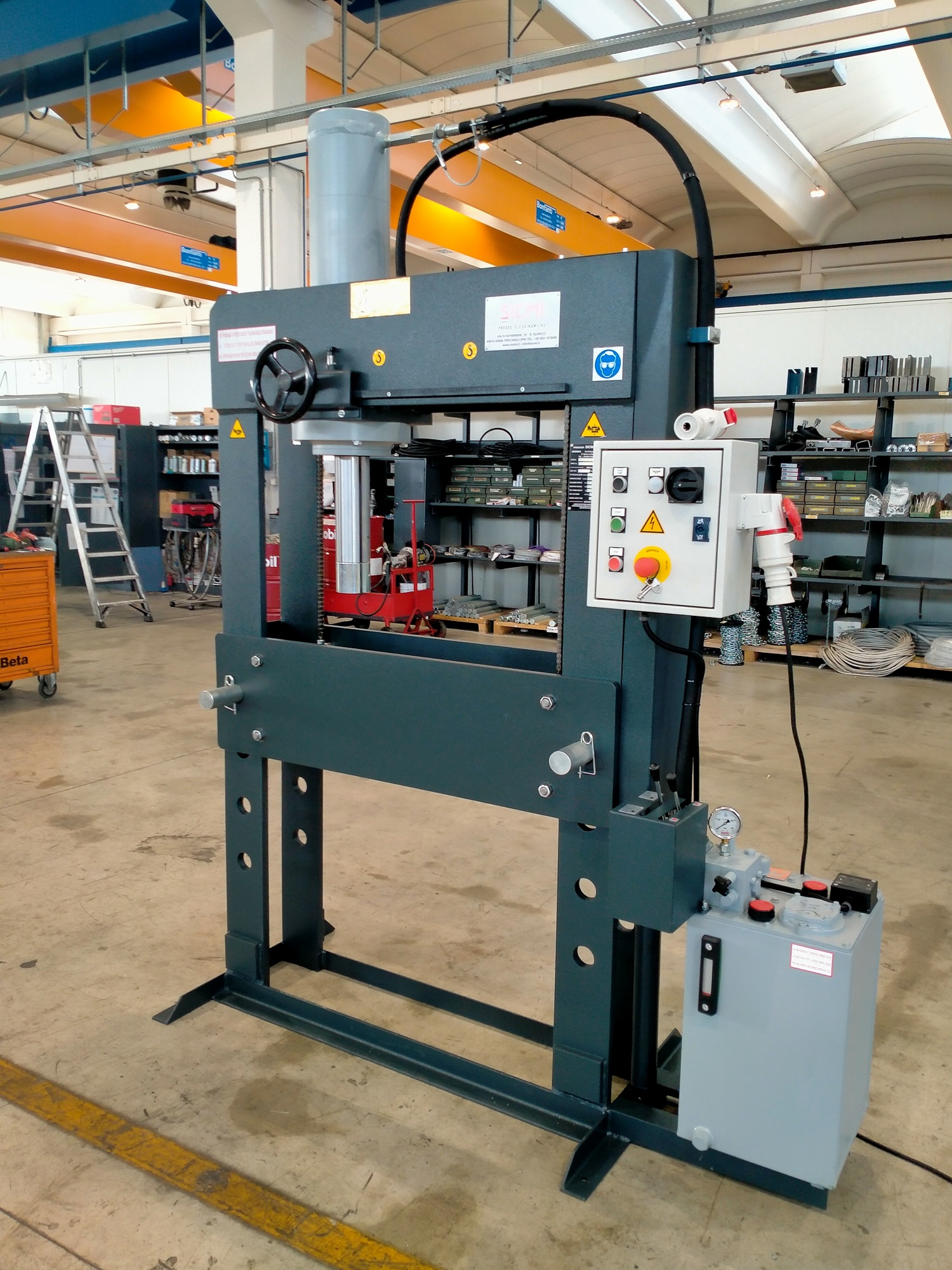

The workshop press with motorized table, PFF model, is characterized by the hydraulic lifting of the platform and the transversal movement of the cylinder.

This press is designed to carry out sheet metal straightening or deformation operations, but also for molding activities and for assembly within a mechanical workshop.

The two-column frame is made of fully welded milled steel and this makes the workshop press with motorized table extremely resistant and solid.

The large front opening between the two uprights allows you to easily position long or wide pieces.

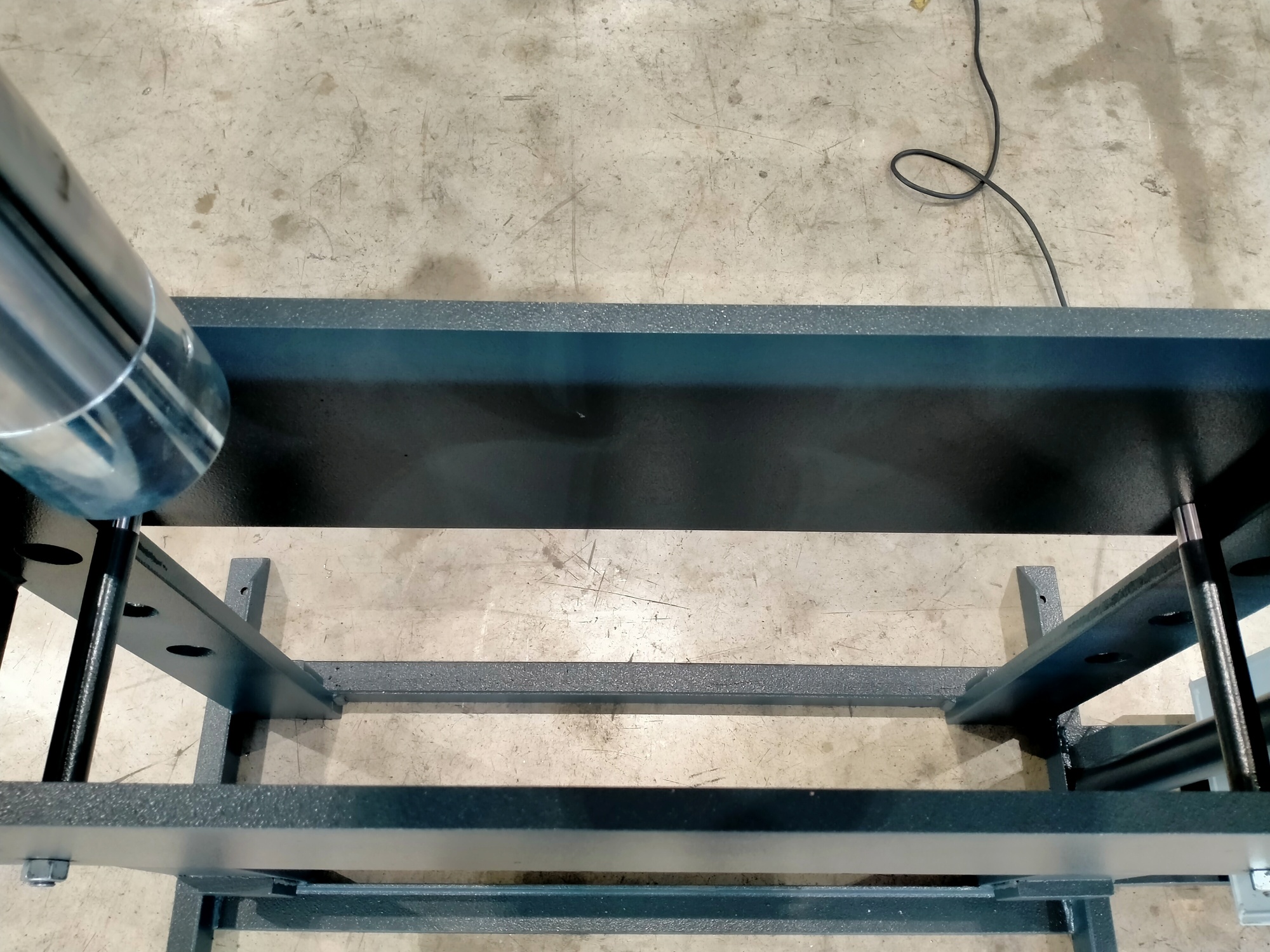

The motorized platform is hollow and this allows processing of the material at height. Work support plates are available as optional equipment.

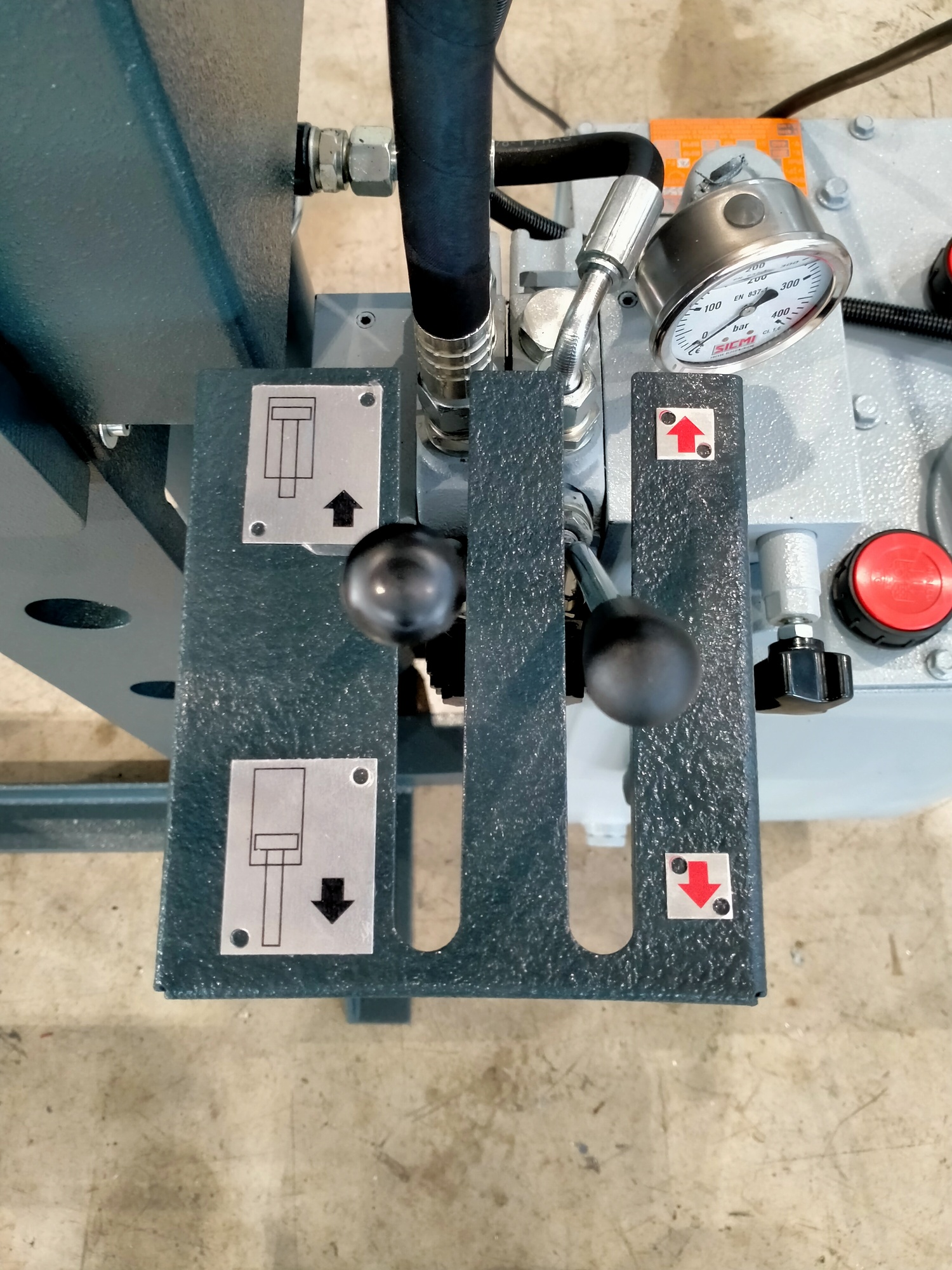

As regards the hydraulic cylinder, the customer can choose between a PFF electro-hydraulic press model with a fixed cylinder, or he can choose the version with a mobile cylinder with transverse movement. This function is manually controlled via a handwheel in models up to 100 tons and with hydraulic movement from 150 tons upwards.

The hydraulic operating controls require the simultaneous use of the lever and the button, as required by current European safety standards.

The PFF electro-hydraulic press is available in models from 70 to 400 tons.

Click to watch the VIDEO