Hydraulic workshop presses are very widespread machine tools within any mechanical or industrial work environment.

These machines use the principle of transmitting pressure through hydraulic oil, which is an incompressible fluid, to exert force on an object. Their operation is relatively simple but highly effective.

A hydraulic press is mainly composed of two hydraulic cylinders, a larger one, called the main cylinder, and a smaller one, known as the pump cylinder. The pump cylinder is connected to a lever or pedal operated by the operator. When the operator operates the lever or pedal, the pump begins to compress the hydraulic oil in the master cylinder, thus creating pressure that is transmitted through a piston inside the master cylinder. This pressure is then exerted on the object positioned between the press plates.

The main advantages of hydraulic workshop presses are many. First of all, they are extremely powerful machine tools and capable of generating an incredible amount of force, allowing you to perform operations such as bending, straightening, pressing and extracting with ease. Furthermore, the uniform pressure exerted over the entire area of the object ensures precise and uniform results.

Within our range of workshop presses we have various models

Click this link to see our assortment of workshop presses

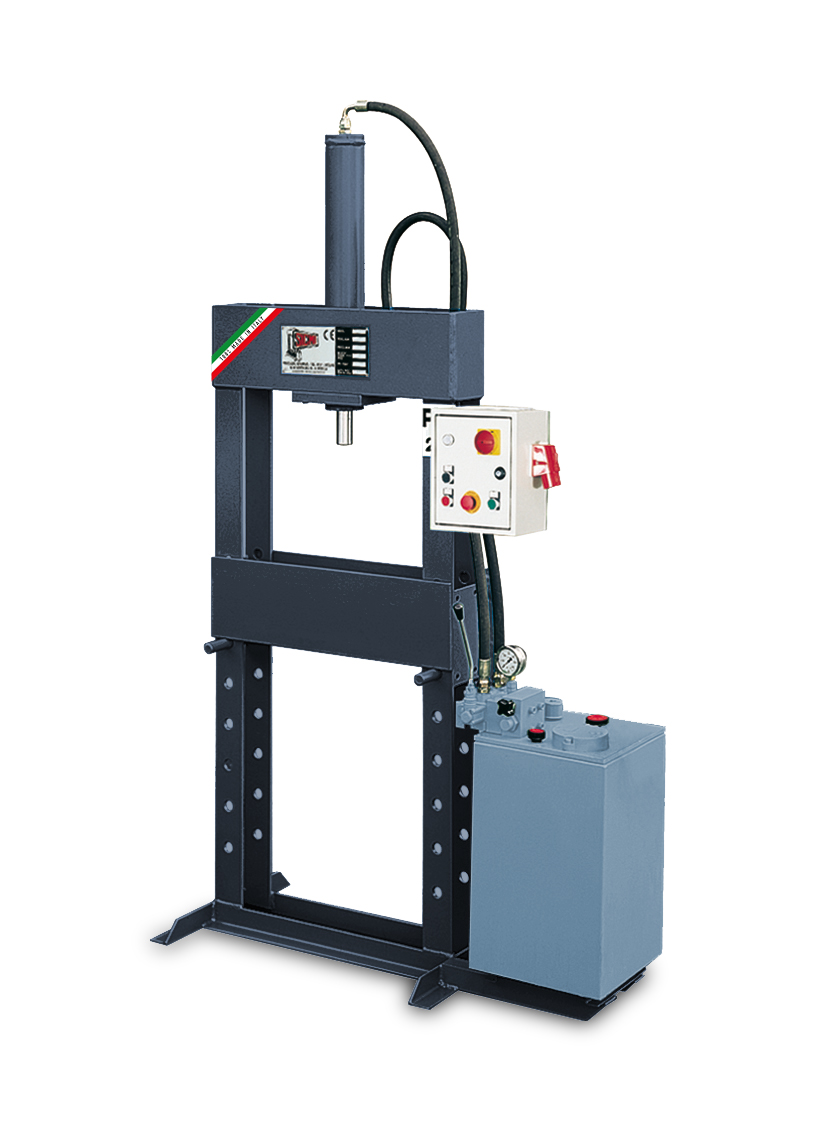

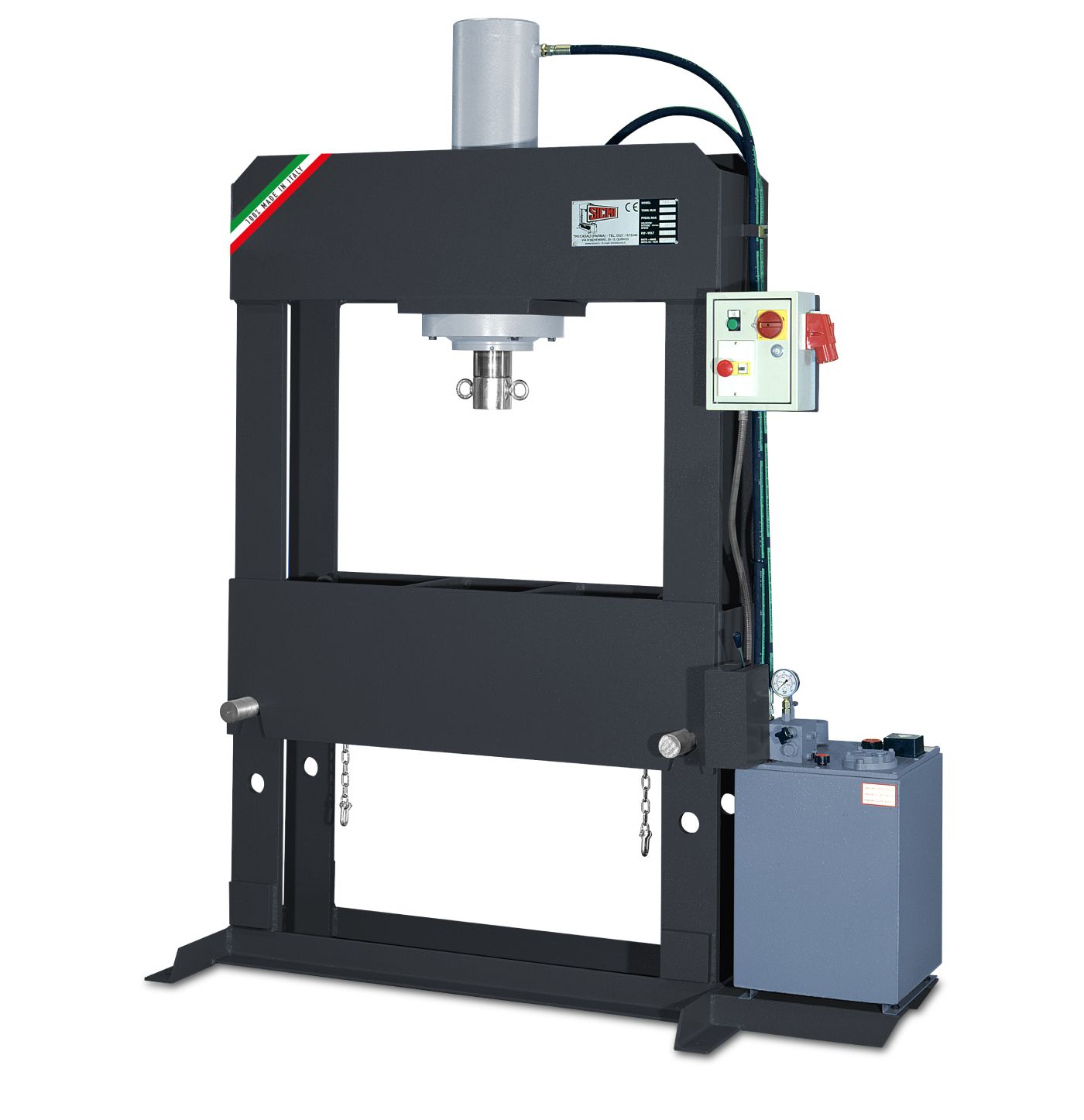

- Workshop press with manual pump – PSM

- Workshop press with 500mm cylinder stroke – PSS

- Workshop press with 350mm cylinder stroke – PSS-NC

- Workshop press with power steering handwheel – PSV

- Motorized workshop press – PFF

- Workshop press with movable cylinder – PFC